Inadequate construction of roof flashing is a major cause of leaking roofs. It remains in the top ten defects identified by the Queensland Building and Construction Commission (QBCC) building inspectors.

The QBCC considers flashing and accessories defective if they leak under weather conditions anticipated by the Building Code of Australia (BCA).

The rectification costs of the defect and resultant damage can be significant for contractors and consumers.

Contractors are responsible for their standard of work and should be aware of correct roof flashing methods. The QBCC can direct contractors to rectify, not only defective work but consequential damage as a result of leaking roofs.

Defective roof flashing systems are a common cause of water penetration in roofs. Examples of roof flashings include:

- cavity flashing

- stepped flashing

- flashing between existing roofs and patio additions

- apron flashing

- hip and valley flashing

- post and pipe penetrations

- capping.

It is essential to install a complete flashing system that intercepts, collects and discharges moisture or water back into the roof stormwater drainage system, not allowing moisture to enter the dwelling.

Apart from malleable flashings, which are fitted on-site, roof flashings should be purpose-made and machine-folded, of material compatible with all material used in the stormwater drainage system.

Both the Australian Standard 1562.1 Design and Installation of metal roof and wall cladding and the SA HB 39 Metal roof and wall cladding installation offer a comprehensive guide. Manufacturers also provide installation specification for their products.

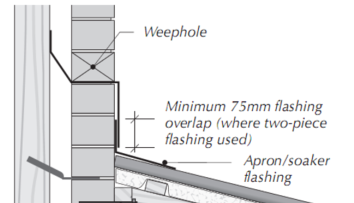

Incorrect veneer cavity flashing to verandah apron flashing noting the incorrect flashing was also provided outside the wall vapour barrier, resulting in moisture pouring into the dwelling.

Source: building inspector.

Cavity flashing fixed to timber frame and fitted to outside of masonry wall.

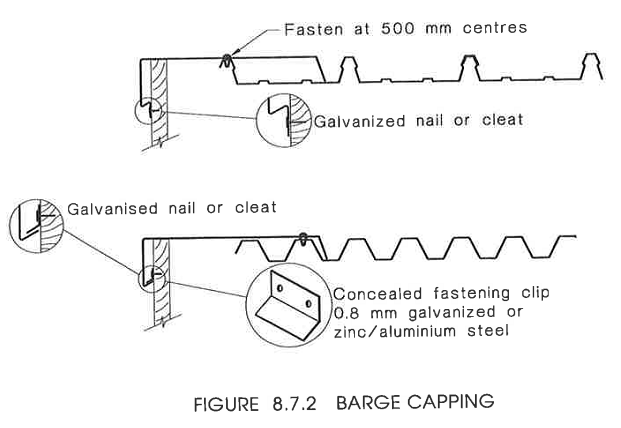

HB39 Figure 8.7.2 Barge cappings.

Cover flashing plus 75mm apron flashing turned up behind.

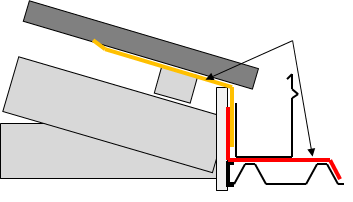

Apron flashing over skillion patio roof extension to an existing roof.

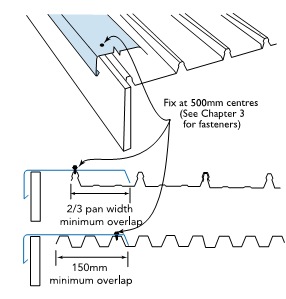

When water can enter through a lap, it must be compressively sealed with an appropriate sealant.

The solutions provided are typical only and have been gathered from current and relevant building codes and Australian Standards. The methodologies described aim to achieve water-tightness by mechanical means rather than an over-reliance upon the use of sealants.

Building projects may often require the adaptation or development of ideas and solutions using the principles of sound waterproofing and flashing techniques as described in this fact sheet.

Note: Manufacturers of roofing and walling goods have developed specific design guides to assist the building industry in achieving compliance with the codes and standards. Readers are encouraged to take advantage of the manufacturer’s design guidelines where compliance with Australian Standard 1170.2 Structural design actions - Wind actions has been stated in their documentation.