Background

Building designers and contractors should be aware that the minimum level of corrosion resistance used by manufacturers of metal framing brackets is Z275 gsm which is appropriate for internal applications only (within the building envelope) that are kept permanently dry. This is not appropriate for external weather-exposed applications subject to repeated wetting.

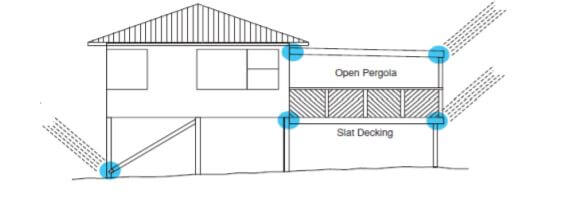

The QBCC has attended sites in response to complaints where non-compliance has been observed with metal joist hangers and other connectors, particularly in balcony and deck constructions that are weather exposed.

These weather-exposed balcony and deck constructions also commonly use treated timbers which can contribute to the accelerated corrosion of metal framing brackets and related fixings.

Where framing brackets are being utilised for applications other than in internal, dry-protected locations or when used in contact with treated timbers, brackets will require a higher level of corrosion protection and durability such as stainless steel.

The failure to utilise joist hangers and other connectors with the required levels of corrosion protection will lead to the early deterioration of these products resulting in a decrease in structural capacity, which in extreme circumstances could eventually contribute to the failure of a structure.

The QBCC has investigated a number of balcony and deck collapses, some of which unfortunately have resulted in death or serious injury to persons.

As part of the QBCC’s charter to maintain and improve building standards, the QBCC and related stakeholders, such as Timber Queensland, have published educational material to increase industry awareness for the need to properly consider the design and construction of structures such as decks and balconies.

Despite the availability of this information, the QBCC is still observing situations where designers and contractors alike are not considering the critical role that these structural connectors perform along with the potential catastrophic consequences of any failure associated with the use of inappropriate hangers and connectors with respect to corrosion resistance.

Timber Queensland has developed a simple process that practitioners are advised to follow to select the correct corrosion resistance for any framing connector. The two (2) criteria that need to be considered are:

- What is the corrosion zone?

- What is the exposure condition?

What are corrosion zones?

Sea spray zone – within 1km from a surf coast or 100m from bayside areas

Coastal zone – 1km to 10km from surf coast or 100m to 1km from bayside areas

Industrial zone – close proximity to industrial complexes where corrosive gases may be emitted

Special hazard zone – around swimming pools or areas within a building where the environment may impact upon the durability of connectors/brackets

Very low and low hazard zone – generally locations not described above.

What is an exposure condition?

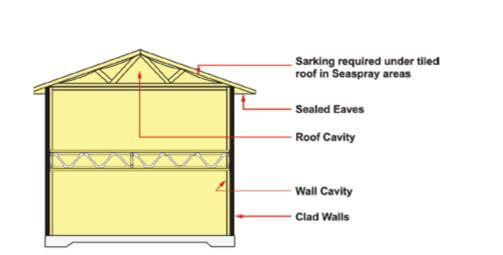

Enclosed – within a fully enclosed building envelope

Sheltered – locations not exposed to rainwater but subjected to wind-blown salts etc.

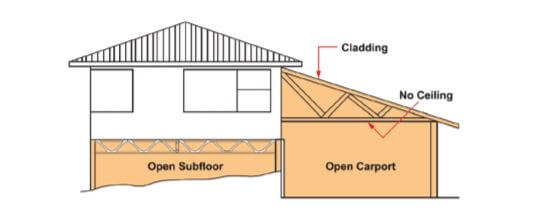

Exposed – locations exposed to weather and rain i.e. decks, pergolas, open sub-floors etc.

What corrosion protection is required?

The following table provides the minimum corrosion protection for metal framing brackets/connectors for the various corrosion zones and exposure conditions.

Going forward

The QBCC has noted that not all manufacturers of framing brackets or connectors may manufacture products to meet the required corrosion resistance ratings or, if manufactured, they are not commonly held in stock by retail hardware outlets and special orders may be required.

Building contractors need to be discerning when purchasing the correct brackets/connectors to ensure appropriate levels of corrosion resistance are provided in any building works for which they are intended for use.

Queensland’s non-conforming building products laws, introduced in November 2017, place a positive obligation on all parties in the chain of responsibility to ensure building products meet all regulatory requirements.

If your supplier or hardware merchant cannot supply framing brackets or connectors with the required level of corrosion resistance, you should obtain your products from another source. Merchants are also required to ensure that documentation is available that evidences how any building product they are offering for sale meets relevant Australian Standards.

Any observed failure to utilise the correct corrosion resistance of joist hangers or other connectors may result in the QBCC directing rectification of that non-compliant work.

The QBCC would recommend all building designers and contractors reference Timber Queensland’s Technical Data Sheet 35 – Corrosion Resistance of Metal Connectors at www.timberqueensland.com.au to better inform themselves as to how compliance can be achieved.

You can also find technical information on the QBCC website.

If building designers and contractors alike take on board the messaging contained within this technical feature and ensure compliance of installed joist hangers and other connectors, they can feel assured their works will be compliant and durable. They can also help to ensure the long-term performance and safe use of decks and balconies constructed in Queensland.

The QBCC acknowledges the invaluable support of Timber Queensland in allowing the use of images and tables.